We offer a wide array of machining services

Machining Services

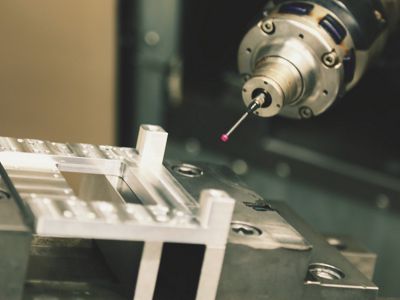

Check out our state-of-the-art equipment that can handle any project you have

Equipment

We are the industry leaders when it comes to steel cutting

Steel Cutting

Learn more about us and our history

About Us

About Us

The Sure-Fab Story Quality Workmanship, On-time Delivery, and One-Stop Manufacturing Sure-Fab first opened its doors in 2002, after founder Joe Hraban discovered the urgent need for higher quality, on-time, full-service manufacturing in North Eastern Minnesota. Since then, Sure-Fab has grown dramatically, becoming a national provider of choice in the manufacturing industry. From materials acquisition, to fabrication and finishing, we get it designed, developed, and delivered to your doorstep. We are dedicated to building lasting, mutually profitable relationships with our customers through shared vision, shared commitment, and superior results.

Steel Cutting Services

Trust your Toughest Steel Cutting Challenges to Sure-Fab. Whatever the intricacies of your design, Sure-Fab can handle it all, in-house.

Precision: Skill and Uncompromising Commitment to Quality

Sure-Fab specializes in precision machining to tight tolerances. We are a team of highly trained specialists, armed with the highest quality equipment. Whether it's a prototype, a short run or a high volume production run, we deliver. Every time.

CNC MACHINING

CNC Horizontal Boring Mills

Toshiba BTD 13 R22

Horizontal Boring Mill

• Table Size 70" x 86"

• Table Capacity 44,000 lbs.

• X axis travel 118"

• Y axis travel 90"

• Z axis travel 63"

• W axis travel 28"

OKK HM-1000S Dual Pallet Horizontal Machining Center

Pallet Size (2 Pallets): 39.37" x 39.37"

Pallet Indexing : 360,000°

Pallet Load Capacity: 5,512 Lbs.

X-Axis Travel: 55.1"

Y-Axis Travel: 43.31"

Z-Axis Travel: 39.37"

Toyoda FH55

Horizontal Boring Mill

• 360° rotating table

• 2 pallet shuttle system

(table sizes 72" x 48")

• X axis travel 23"

• Y axis travel 28"

• Z axis travel 22.1"

• Maximum load 1,760 lbs

CNC Vertical Machining Centers

HNK HQ-12 Gantry Style

CNC Vertical Machining Center

• 2 pallet shuttle system (table sizes 72" x 60"

with universal sub-plate)

• X axis travel 118"

• Y axis travel 90"

• Z axis travel 15.7"

• W axis travel 39.4"

• Maximum load 11,000 lbs

• 15 hp 900 RPM right angle head

• Renishaw touch probe

Toyoda FV 1680

CNC Vertical Machining Center

• Table size 68.9" x 31.5"

with universal sub-plate

• X axis travel 63"

• Y axis travel 31.5"

• Z axis travel 31.5"

• Maximum load 4,400 lbs

• Renishaw touch probe

Toyoda FV1365

CNC Vertical Machining Center

• Table size 56.1" x 25.6"

with universal sub-plate

• X axis travel 51.2"

• Y axis travel 25.6"

• Z axis travel 23.6"

• Maximum load 2,866 lbs

• Renishaw touch probe

CNC Turning Centers

Puma 400 MB

CNC Turning Center

• Maximum turning diameter 24"

• Maximum turning length 41.1"

• Live tooling

• Face and side milling

• Drilling and tapping

PUMA 400 LC

CNC Turning Center

• Maximum turning diameter 24"

• Maximum turning length 82.4"

ROBOTIC WELDING

ABB 2400L (Long arm)

• Single axis positioner with 54" adapter plate (can handle parts 4' tall)

• Single axis positioner with 13' table

• Stationary fixture table 5'x10'

• 23' track

• S4C controller

• RobotStudio 5.61 w/ ArcWeld PowerPac (the latest offline programming software available)

• 0.052" solid core wire

• C10 gas

STEEL CUTTING

Plasma Oxyacetylene Cutting Systems

ALLtra PG-14 Heavy Duty Industrial Cutting Machine with Plasma Bevel Head and 2 Oxyfuel Stations

• Cutting width 10 ft.

• Cutting Length 26 ft.

Hypertherm Plasma System (*Including TrueHole) Hypertherm HPR-400XD(r)

• High Speed Positioning

• Automatic Height Control

• Crash Protection

• Servo Control & Encoder Positioning

ALLtra Plasma Bevel Station

• Cutting width 10 ft

• Cutting Length 26 ft

• Automatic Contour Bevel Station

• Single Axis Bevel Station

• Robotic Positioning

• Breakaway Crash without need for Re-Alignment

2 Oxyfuel Cutting Stations

• ALLtra Intelligent Design

• Automatic gas control offered on the PG Series Cutting Machines

HEM V100LA-2 FULLY AUTOMATIC VERTICAL BAND SAW

SPECIFICATIONS:

Throat Depth 18"

Capacity 90 Degrees 18" x 20"

Head Tilt 45 Degrees Left or Right

Capacity at 45 Degreed 18" x 14"

Sure-Fab

Sure-Fab LLC is a high quality manufacturing company in northeastern Minnesota specializing in a wide range of manufacturing services. Our large production facility enables us to accommodate projects of all sizes. Because we know that top quality is only achieved through top craftsmanship, we invest in a team of highly experienced welders. Sure-Fab welders are experts, highly respected in their field. Each has a minimum AWS D1.1 certification, and the talent and experience to produce superior products every time. Using our precision fixture tables for MIG and TIG welding of mid to high alloy steels, aluminum, and stainless, they take your designs to flawless reality. This team has nine complete welding stations at their disposal, including 400-650 amps, equipped with two 4,000 lb jib/hoists, and duel feeders with various wire sizes and inert gas combinations, and three positioners with 5,000 lb capacity.

About Us

Since 2002, Sure-Fab LLC has been the contract manufacturing leader for high quality, on-time, full-service manufactured parts in northeastern Minnesota

Hours

Contact Us

Phone:

218-834-2773

1549 Highway 2

Two Harbors, MN 55616

Email Us

bjohansen@surefab.net

Blog

Check out our blog for our latest news and specials